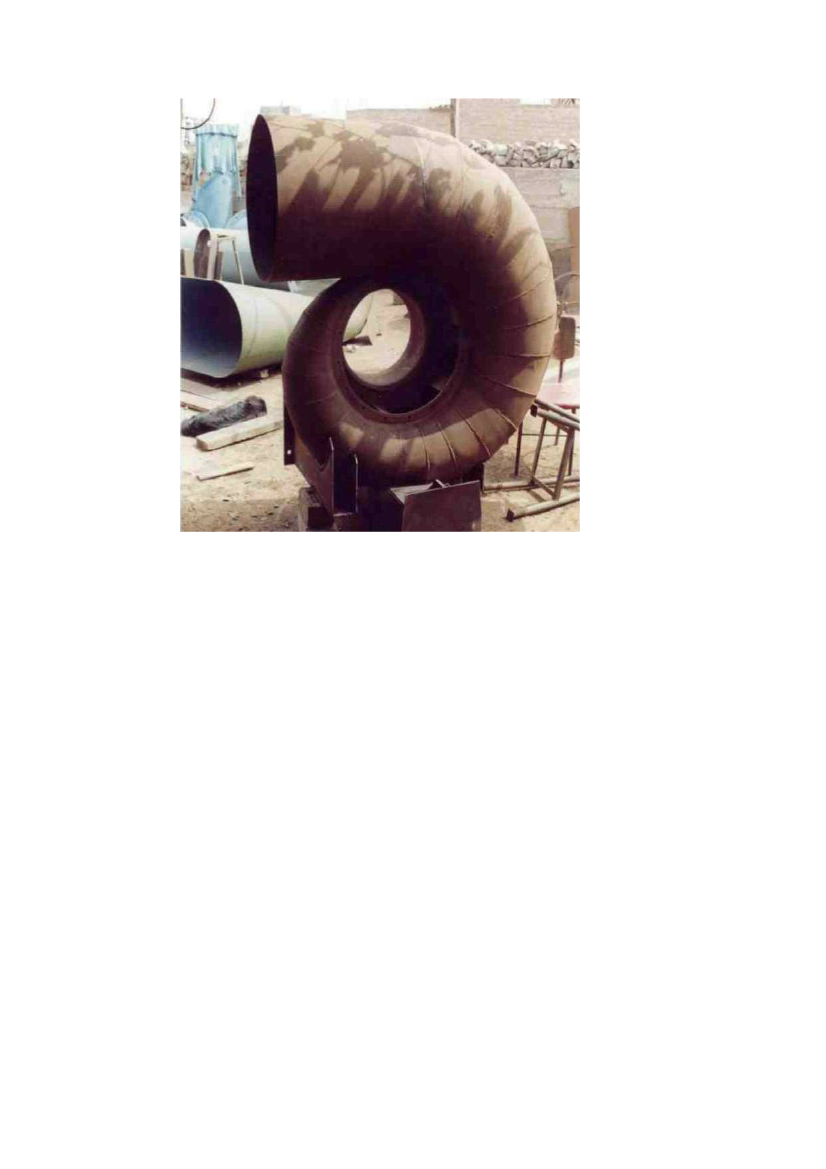

Figure 13: Spiral after the process is complete

Filing down. When both the housing and the suction tube segments

are arc-welded together, the end result will have burring and small

protrusions caused by the welding bead both inside and outside the

housing and suction tube. This must be removed. Removing any

burring and proud seams on the interior is advisable in order to reduce

water friction, thereby limiting any loss in the area, while on the outside

it serves an aesthetic purpose.

The filing process involves using a hand grinder with grinding discs and

circular abrasives (for the grinder), followed by files and abrasive paper

as required, beginning with a coarse grain and finishing off with finer

grains.

Painting. The surface should be completely cleaned before painting,

using a clean rag and thinners or any other substance to remove any

build-up of dirt and grease.